Lower carrying costs, fewer stockouts, faster order cycles, better customer experience—without adding headcount.

SMBs can use AI to make supply chains faster, cheaper, and more predictable. AI improves demand forecasting, inventory management, and logistics routing so you stock the right items, avoid rush fees, and deliver on time. With solid cybersecurity and data governance, AI becomes a safe force multiplier for lean teams.

Introduction: The SMB Supply Chain Reality

Small and medium‑sized businesses (SMBs) operate in a world of thin margins, unpredictable demand, and constant customer pressure for speed and reliability. Many teams still stitch together spreadsheets, email threads, and tribal knowledge to plan purchases, balance inventory, and book carriers. That approach can work in calm waters—but when a supplier slips, a promotion over‑performs, or a snowstorm hits a key lane, manual methods crack. Artificial Intelligence (AI) changes the math for lean teams. It doesn’t replace planners or dispatchers; it gives them sharper sightlines and faster feedback loops. With the right data footing, AI turns your historical orders, lead‑time logs, and fulfilment events into forward‑looking signals you can act on—before exceptions hurt customers or cash flow.

This guide is pragmatic. We focus on three high‑leverage use cases—demand forecasting, inventory optimisation, and logistics routing—because they generate measurable gains inside 90 days. We pair them with a secure‑by‑design approach so your AI initiative does not widen the attack surface or expose sensitive pricing, supplier terms, or customer data. You’ll find step‑by‑step actions, KPIs to track, a vendor checklist, and a change‑management cadence that sticks. Every recommendation is sized for Canadian SMBs—distributors, light manufacturers, e‑commerce brands, and retailers with 5–250 employees—who need enterprise‑grade outcomes without enterprise overhead.

If you take only one idea from this article, let it be this: success comes from discipline, not magic. Clean a small slice of data, pilot with explicit targets, measure relentlessly, and scale what works. That rhythm—plan, pilot, prove, protect—compounds results quarter after quarter while reducing risk. Read on for a clear playbook you can start this week.

Why It Matters for Canadian SMBs

Cash flow discipline. Inventory is deferred cash. When forecasts improve and reorder points reflect real lead‑time variability, you shrink safety stock without harming service levels. That frees CAD $ for marketing, hiring, or capital projects. The compounding benefit is fewer write‑downs of aged stock and less warehouse sprawl.

Customer trust. Accurate ETAs and consistent fill rates create repeat buyers and strong reviews. AI‑assisted routing improves last‑mile performance and communication—customers get proactive updates, fewer missed windows, and tighter delivery ranges. In B2B, reliability becomes a differentiator when competitors are still firefighting.

Resilience to shocks. Markets swing. AI surfaces early signals—demand spikes, supplier slips, substitution patterns—so planners can reallocate stock, adjust POs, or throttle promotions. Scenario forecasts (base/conservative/aggressive) make trade‑offs explicit for executives and finance.

Cyber resilience. Lean teams are prime targets. A single phishing email can trigger ransomware that freezes WMS/TMS and stops revenue. Secure AI programmes implement MFA/SSO, EDR/XDR with 24/7 monitoring, immutable backups, DLP, and role‑based access. Vendor reviews (SOC 2/ISO 27001) and clear data residency keep compliance and risk in check.

Canadian context. Factor weather disruptions, regional holidays, bilingual communications, and cross‑border customs realities. Align with PIPEDA: minimise PII, encrypt data, and honour access requests. These aren’t checkboxes; they’re the guardrails that let you scale confidently.

Bottom line: AI isn’t a moonshot. It’s disciplined operations with better instruments. Start narrow, measure, secure, and expand.

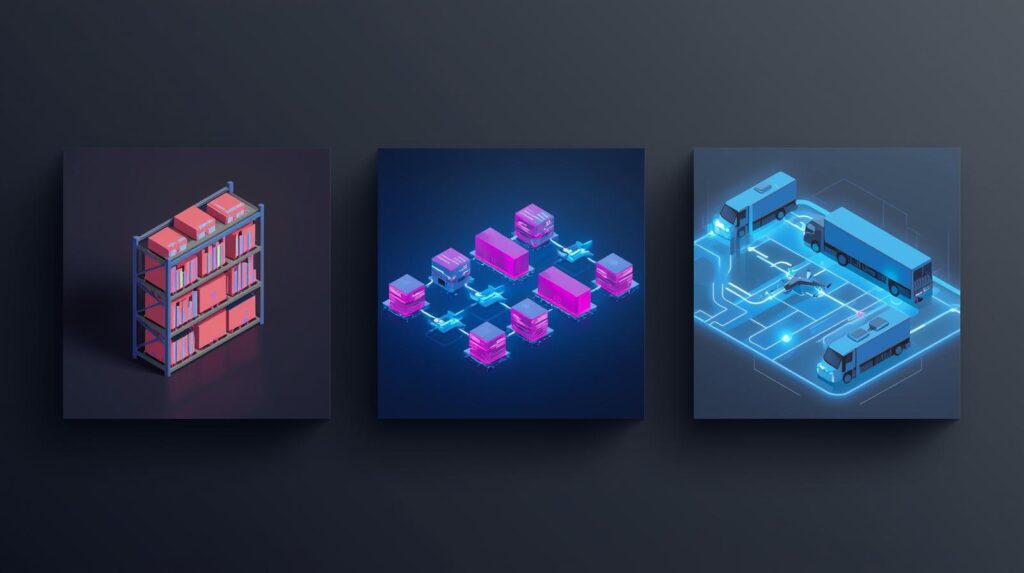

Core AI Use Cases (Step-by-Step)

1) Demand Forecasting (Data‑driven, not guesswork)

Getting the forecast “good enough” changes everything downstream. Begin by cleaning 24–36 months of order lines, flagging stockout days, mapping promotions, and normalising units. Segment SKUs: ABC by revenue/margin contribution and XYZ by demand variability. Use the simplest model that consistently beats your baseline—often exponential smoothing or gradient boosting before deep learning. Generate SKU × location weekly forecasts with confidence intervals (P50/P90) and track MAPE, bias, and resulting fill rate.

Embed a cadence: publish forecasts every week, hold a brief review to triage exceptions, and document decisions. Configure alerts when demand deviates beyond thresholds (e.g., >2σ), when lead times slip, or when promo uplifts differ from plan. Pair forecasts with scenario planning—base, conservative, aggressive—so procurement and finance can run cash and capacity impacts. New SKUs need proxies or hierarchical methods; discontinued items require decay.

Common pitfalls: training on periods where you were out of stock (the model “learns” false low demand), overfitting with too many features, or ignoring promo calendars. Keep humans in the loop for market intelligence your data doesn’t know—competitive launches, weather anomalies, or one‑off events. Measure accuracy monthly and retrain quarterly or after major assortment changes.

Business impact: lower safety stock, fewer expedites, smoother labour planning, and a credible baseline for S&OP. Forecasts will never be perfect—but consistently better than guesswork is a major win.

2) Inventory Optimisation (Right stock, right place)

How it works:

- Translate forecast + lead time variability into dynamic reorder points and min/max levels based on service targets.

- Use multi‑echelon logic if you hold stock at both DC and stores.

Outputs:

- Replenishment proposals per SKU/location with suggested order quantities.

- Stock health dashboard showing days of supply, aged inventory, and at‑risk SKUs.

Key levers:

- Service level vs. working capital trade‑off.

- Lead time realism: use actuals, not vendor promises.

- Transfer balancing: move stock between locations before buying more.

Watch‑outs:

- Minimum order quantities (MOQs) can inflate stock—negotiate MOQs or align reorder cadence.

- New SKUs (no history) need heuristics and proxy demand.

3) Logistics & Route Optimisation (Faster, cheaper, greener)

How it works:

- Vehicle routing problem (VRP) solvers consider capacity, delivery windows, driver hours, traffic, and weather.

- Dynamic re‑optimisation when orders or conditions change midday.

KPIs: cost/km, on‑time %, drop count per route, CO₂/km (optional).

Best practices:

- Lock customer delivery windows; gather geocodes; standardise driver notes.

- Use live traffic feeds; alert customers with accurate ETAs.

- Keep a “hot spare” vehicle/driver plan for peak days.

Secure by Design: Cyber Risks You Must Control

AI projects connect systems that attackers love: ERP, WMS/TMS, e‑commerce, identity, and cloud storage. Threats include ransomware that freezes fulfilment, credential‑stuffing that hijacks admin portals, API token abuse across integrations, misconfigured storage leaking customer/supplier data, and model abuse that skews recommendations.

Control the blast radius with layered defences:

- Identity first: MFA and SSO everywhere; conditional access for risky logins; least privilege; quarterly access reviews for users and service accounts.

- Detect & contain: EDR/XDR on endpoints and servers with a 24/7 SOC to triage and contain fast. Measure mean time to contain.

- Email/DNS/Web security: advanced filtering, link isolation, and domain‑based protections to blunt phishing and C2 traffic.

- Backups/BCDR: immutable off‑network copies, tested restores (RTO/RPO) and documented runbooks. Tabletop a WMS‑down scenario.

- Network segmentation: separate office IT, warehouse devices, and cloud services; block lateral movement; enforce least‑route firewall rules.

- Data safeguards: classification, encryption at rest/in transit, DLP for supplier terms and PII, audit logs for access and exports.

- Vendor due diligence: SOC 2/ISO 27001, data residency clarity, breach notification SLAs, and export/exit options to avoid lock‑in.

- Governance: change logs for models and parameters; human approval for automated POs; monitoring for data drift and prompt‑injection patterns.

Security isn’t a tax—it’s uptime insurance. Bake it in from day one so optimisation doesn’t create new single points of failure.

90‑Day Implementation Roadmap

Owner: Operations lead. Stakeholders: IT/Security, Finance, Supplier Manager.

Days 0–15: Baseline & Data Prep. Define KPIs (stockouts/week, fill rate %, carrying cost %, on‑time %, pick accuracy). Extract order lines, inventory snapshots, PO history, lead times, returns, and promos. Run two data‑quality sprints: de‑duplicate SKUs, normalise units, flag stockout days, and label new/discontinued items. Cyber hardening: enforce MFA, patch critical systems, verify EDR/XDR coverage, and perform a backup restore test. Lock baseline MAPE and service level.

Days 16–45: Pilot Forecast + Replenishment. Scope 10–20 SKUs across 1–2 locations with a mix of A/B and X/Y/Z items. Train a baseline model and backtest. Set a target (e.g., −25% MAPE vs. baseline). Publish weekly forecasts, generate replenishment proposals, and require human approval. Build a stock health dashboard and anomaly alerts for demand spikes or late POs. Document early wins and cash impact.

Days 46–75: Logistics Optimisation. Gather geocodes, delivery windows, vehicle capacities, driver shifts, and depot constraints. Run an A/B route test; measure cost/km and on‑time %. Integrate live traffic/weather and enable dynamic re‑routing. Turn on customer ETA messaging to cut failed deliveries.

Days 76–90: Scale & Secure. Expand to top 80% revenue SKUs and all active locations. Formalise governance (RBAC, audit logs, encryption), enforce segregation of duties for approvals, and run a ransomware tabletop (WMS‑down) to validate restore runbooks. Publish SOPs, RACI, and meeting cadences.

This cadence proves value fast and builds confidence to scale.

Cost & ROI

Start with a conservative model. Assume CAD $4M average inventory, 18% carrying cost, and 10% baseline forecast error. Carrying cost is roughly $720k/year. If AI‑guided replenishment trims average inventory 6–12% while holding service levels, carrying cost savings land between $43k–$86k. Add $30k–$60k from fewer expedites and lost sales due to stockouts, plus $20k–$35k from route efficiencies. Conservative total: about $122k/year.

Costs vary. Expect $2k–$5k/month for tooling/services in pilot/early scale, plus modest internal time for data prep and process changes. Payback is often under 12 months when pilots focus on A‑items and high‑cost lanes, and when parameters are reviewed monthly. Sensitivities matter: the tighter your service targets, the more working capital you’ll need; unstable lead times inflate safety stock; and MOQs can blunt savings unless renegotiated.

Track ROI with a simple dashboard: baseline vs. current MAPE, fill rate, inventory turns, stockouts/week, expedite spend, cost/km, and on‑time %. Attribute savings honestly—separate seasonal effects and promotion impacts. Re‑invest early gains into data quality (fewer errors, faster updates) because clean data amplifies every down‑stream benefit.

Data Governance & Compliance (Canada) – Practical Controls

Canada’s PIPEDA requires purpose‑limited collection, transparency, and safeguards for personal information. In supply chains, that means minimising PII in operational datasets, encrypting data at rest and in transit, and honouring access requests within defined timelines. Practically, keep PII (names, addresses, payment data) logically separated from forecasting datasets when feasible; tokenise where appropriate.

Document data flows: sources (ERP, WMS/TMS, e‑commerce), transformations (ETL/iPaaS), storage (warehouse/object store), and outputs (dashboards, replenishment proposals). Maintain a vendor register with data residency and processing locations, plus breach notification SLAs. Enforce role‑based access control, rotate keys and tokens, and ban secrets in code repositories; use a secrets manager.

Make auditability routine: version forecasts and parameters, log automated order approvals, and preserve anomaly decisions for review. Establish data retention aligned to business and regulatory needs; avoid keeping sensitive data “just in case.” Train staff on acceptable data use and phishing awareness—human error remains the biggest risk.

Strong governance turns compliance into a competitive edge: customers and partners trust you with their data, and operations benefit from consistent, high‑quality inputs.

Operating Model & Tech Stack

A lean operating model paired with a right‑sized stack turns AI from theory into daily practice. The Operations Lead owns KPIs and decision rights, approving replenishment proposals and signing off route plans. A Planner/Buyer monitors exceptions, tunes parameters, and manages supplier communications, while IT/Security runs integrations, identity and access management, endpoint protection, and backup/BCDR drills. Finance validates cash impacts, reconciles inventory accounting, and confirms ROI. An Executive Sponsor removes roadblocks and keeps the cadence tight so wins compound.

Under the hood, core systems include POS/e‑commerce, ERP, and WMS/TMS—plus any spreadsheets that still matter. A lightweight iPaaS or ETL pipelines data into a secure object store or warehouse, where analytics models generate weekly SKU×location forecasts with MAPE/bias reporting and produce optimisation outputs for reorder quantities and routes. Dashboards surface stock health, forecast accuracy, and route KPIs for the S&OP‑lite review. Security is built‑in, not bolted on: MFA and SSO across users and services; EDR/XDR on endpoints and servers monitored by a 24/7 SOC; SIEM for centralised telemetry; immutable backups with tested restores; and Zero Trust segmentation between office, warehouse, and cloud. This combination lets a small team make fast, confident decisions—safely.

Change Management

Technology fails when habits don’t change. Anchor your AI initiative in short, visible cycles. Run a weekly S&OP‑lite: review forecast accuracy, exceptions, supplier delays, and route KPIs. Keep it to 30 minutes with a standing agenda. Publish decisions and follow‑ups in a shared log.

Create compact playbooks for common scenarios: demand spike, supplier slip, looming stockout, or carrier capacity crunch. Each playbook should list triggers, owners, actions, and communication templates. Record quick Loom‑style walkthroughs so new team members can self‑serve training. Tie incentives to shared KPIs—fill rate, turns, on‑time delivery—so functions pull in the same direction.

Communicate wins early: “We cut expedites by 18% on the pilot SKUs this month.” Momentum matters. Retire old reports and manual steps to avoid duplicate work. Finally, appoint a visible executive sponsor to unblock decisions and reinforce priorities when trade‑offs arise.

Case Vignette

A Montréal distributor with 38 employees managed a 4,200‑SKU catalogue across one DC and two satellites. Demand was lumpy, promotions unpredictable, and overtime frequent. The team launched a 90‑day AI pilot on 60 SKUs representing 40% of revenue. After two data‑quality sprints, they trained a simple model and published weekly SKU×location forecasts with confidence intervals. Replenishment proposals were reviewed by the buyer for the first month, then auto‑approved within guardrails.

Within six weeks, MAPE dropped from 27% to 17%. By day 90 it stabilised at 14%. On‑hand inventory fell 11% while service levels held at 96%. Rush POs declined, and warehouse overtime eased. For last mile, an A/B test showed 7% lower route costs and 18‑minute tighter ETA accuracy. Customer “where’s my order?” calls dropped noticeably.

Security was tested when a convincing phishing email targeted a warehouse supervisor. EDR/XDR detected lateral movement attempts; the 24/7 SOC contained the incident in 12 minutes. Operations continued without downtime, validating the decision to secure first and automate second. The pilot’s success funded expansion to the top 80% revenue SKUs.

Lesson: Start narrow, measure obsessively, secure everything, then scale.

Final Thoughts

AI isn’t a silver bullet, but it is a reliable co‑pilot for disciplined operators. Treat data like an asset, security like uptime insurance, and pilots like investments that must earn their keep. When you combine better instruments (forecasts, reorder logic, routes) with tighter governance and weekly accountability, your supply chain becomes calmer, your customers more loyal, and your cash flow healthier. Start with one product family, one lane, one dashboard. Prove it, learn, and expand. The compounding effect over four quarters will feel less like a project and more like a cultural advantage your competitors can’t easily copy.

Featured links:

Managed Cybersecurity for SMBs

FAQ:

Do we need perfect data to start with AI forecasting?

No. Begin with your cleanest 12–24 months of order lines, flag stockout days, map promotions, and normalise units. Accuracy improves each cycle. Document assumptions and compare against your current baseline monthly.

How do we avoid over-stocking when service levels are high?

Use dynamic reorder points based on forecast variability and actual lead-time distributions. Segment SKUs (ABC/XYZ), apply different service targets by class, and review parameters monthly. Transfer balance idle stock before issuing new POs.

What security must be in place before piloting AI?

Enable MFA/SSO, least-privilege access, and EDR/XDR monitored 24/7. Maintain immutable, tested backups and segment warehouse/office/cloud networks. Log model changes and require approvals for automated orders to prevent abuse or mistakes.

How fast can we see ROI?

Most SMBs see early wins in 30–60 days on pilot SKUs: lower MAPE, fewer expedites, clearer ETAs. With disciplined rollout, conservative annual savings often exceed CAD $120k for a $4M inventory footprint. Results vary by data quality.

PROBLEM

Volatile demand, thin margins, manual planning; imbalanced inventory; inefficient routes; rising cyber risk.

IMPACT

Cash trapped in stock, stockouts and late deliveries, overtime and rush fees, outage risk.

SOLUTION

Secure, right-sized AI—weekly SKU×location forecasting, dynamic reorder points with human-in-the-loop, AI-assisted routing; wrapped with MFA/SSO, EDR/XDR 24/7 SOC, immutable backups, DLP.

CONSEQUENCE

Adopt—lower carrying costs, fewer stockouts, 5–8% route savings, faster ETAs, sub-year payback. Ignore—more cash drag, service erosion, and heightened breach risk.

Our Cybersecurity Guarantee

“At Fusion Cyber Group, we align our interests with yours.“

Unlike many providers who profit from lengthy, expensive breach clean-ups, our goal is simple: stop threats before they start and stand with you if one ever gets through.

That’s why we offer a cybersecurity guarantee: in the very unlikely event that a breach gets through our multi-layered, 24/7 monitored defenses, we will handle all:

threat containment,

incident response,

remediation,

eradication,

and business recovery—at no cost to you.

Ready to strengthen your cybersecurity defenses? Contact us today for your FREE network assessment and take the first step towards safeguarding your business from cyber threats!